Woodworking Accessories Tips

Brad Point Boring Bit – The Ultimate Guide for Clean, Accurate Woodworking Holes

Section:

-

What is a Brad Point Boring Bit?

-

Key Components and How It Works

-

Benefits of Brad Point Bits

-

Where to Use Them

-

Industrial-Grade Features

-

How to Choose

-

FAQs

-

Conclusion

What is a Brad Point Boring Bit?

A Brad Point Boring Bit (aka “lip and spur” bit) is a specialized woodworking drill bit designed for precise drilling with minimal tear-out. It features a sharp brad center point to anchor the bit and outer scoring spurs that slice wood cleanly.

Compared to standard twist drill bits, Brad Point bits stay centered, create clean hole edges, and eliminate the mess of splinters and jagged rims — making them perfect for cabinet drill bit use and precision joinery.

Key Components and How It Works

- Center Pin (Brad Point): Prevents wandering and holds bit steady.

- Scoring Spurs: Slice fibers before boring begins, reducing tear-out.

- Twist Flutes: Efficient chip removal, cool drilling, longer bit life.

This design ensures smooth entry, consistent hole size, and reduced cleanup — all crucial for professional woodworking projects.

Why Choose a Brad Point Bit? Key Benefits Explained

✅ No Wandering

Brad points bite instantly into the wood surface — no skidding, no guessing.

✅ Clean Hole Edges

Scoring edges shear the fibers before drilling, producing a perfectly smooth hole. Great for visible joinery and dowel alignment.

✅ Accurate Hole Size

No over-drilling — your 5mm bit makes a true 5mm hole, ideal for dowels and shelf pins.

✅ Works at Angles

Need to drill at a 15° angle? The brad point keeps you centered where twist bits would drift.

Applications: Where Brad Point Bits Shine

🔩 Cabinet making & joinery

🔩 Bookshelves and furniture assembly

🎯 Dowel hole drilling

📐 Drilling shelf pin holes

🧰 Template-guided or jig-based drilling

Industrial-Grade Brad Point Bits: More Than Just Sharp

Take it up a notch with Amana Tool® Industrial Brad Point Boring Bits. These aren’t your average bits:

★ Carbide-Tipped for Durability

Holds an edge 3–5x longer than HSS — ideal for production environments or repeat drilling.

★ PTFE Non-Stick Coating

Reduces friction and chip clogging

Drills cooler, prevents burning

Applied at 570°F, it clears itself during use — no sanding required

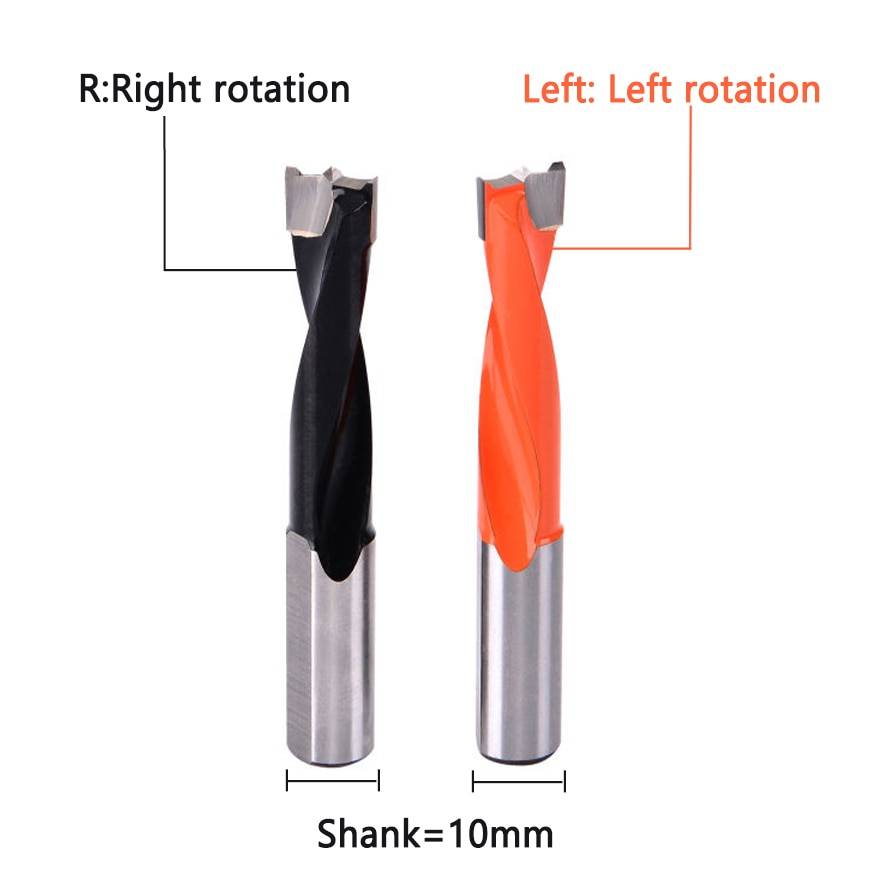

★ Right-Hand vs. Left-Hand Bits

RH (clockwise): Standard use for hand drills and presses

LH (counter-clockwise): Specialty machines, or for removing broken screws

How to Choose the Right Brad Point Bit

Ask yourself:

Will I use this regularly? (If yes — 100% worth it)

Is precision critical in my work? (Cabinets, dowels, face frames?)

Does cleanup slow me down? (Clean holes = faster builds)

✅ If you said yes to any of the above — time to add a few Brad Point bits to your toolbox.

FAQs: Brad Point Bits Answered

Q: What materials can Brad Point bits be used on?A: Best for wood — softwoods, hardwoods, plywood, MDF. Not for metal or masonry.

Q: Can I use Brad Point bits in a hand drill?A: Yep! Just keep it steady — they shine even more with drill presses or jigs.

Q: How do I maintain a Brad Point bit?A: Keep clean and avoid metal. PTFE coatings (like Amana’s) resist gumming and help bits run cool.

Q: Are they more expensive?A: Slightly — but time saved on sanding, mistakes, and redos? Totally worth it.

Conclusion: Don’t Compromise on Precision

When precision, speed, and clean finish matter, the Brad Point Boring Bit delivers. You get cleaner holes, better alignment, and less sanding — all without needing advanced skills.

🔁 So next time you think about grabbing a twist bit, ask: Would a Brad Point do it better? (Spoiler: Yes.)

📌 Pro Tip: Bookmark this page and check out our Recommended Brad Point Bits → for your next woodworking upgrade.