Woodworking Accessories Tips

5 Types of CNC Woodturning Tools and Their Best Uses for Woodworking

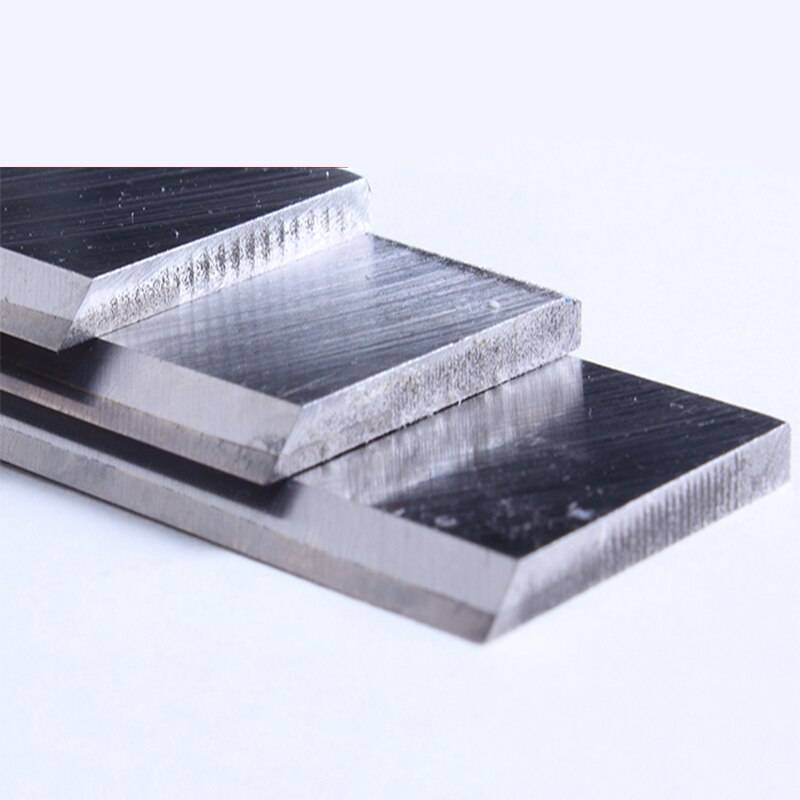

1. Normal Lathe Cutters

Overview

Normal lathe cutters are simple, single-structured tools made primarily from high-speed steel (HSS). They are designed for softwood and semi-hardwood turning and are widely used for general woodworking projects.

Key Features:

- Made from high-speed steel (HSS)

- Best for softwood and semi-hardwood

- Cost-effective but requires regular sharpening

- Common in hobby and small-scale woodworking

Best Applications:

- General wood shaping and finishing

- Suitable for beginners and small-scale production

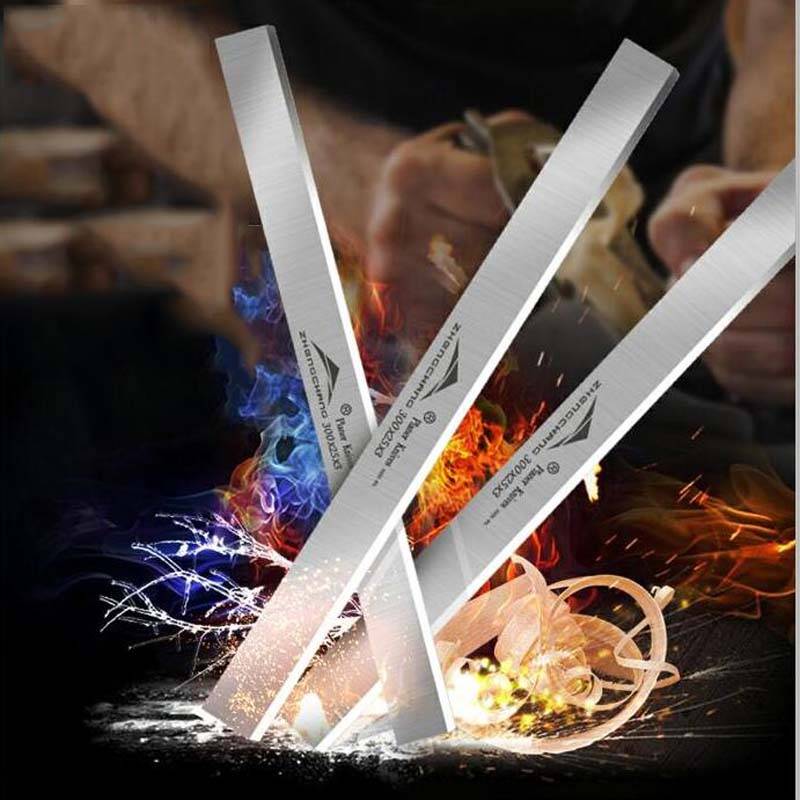

2. Carbide Welding Woodturning Tools

Overview

Carbide welding woodturning tools consist of a high-speed steel body with a carbide blade welded onto a slot. This combination provides greater durability and is more suitable for cutting harder woods while maintaining affordability.

Key Features:

- Enhanced durability due to carbide blade

- Ideal for hardwood and semi-hardwood machining

- Lower replacement costs compared to HSS tools

- More efficient than standard lathe cutters

Best Applications:

- Professional woodworking shops

- Cutting denser hardwoods with precision

3. Wood Lathe Cutters with Changeable Knife Heads

Overview

This type of cutter features replaceable blades that are clamped onto the cutter bar, eliminating the need for welding. It extends tool life and reduces operational costs.

Key Benefits:

- No high-temperature welding, avoiding blade hardness reduction

- Extended tool lifespan and higher efficiency

- Reusable tool holders, reducing overall tool costs

- Adjustable blade positioning for longer usability

- Integrated chip breaker for efficient debris removal

Best Applications:

- Long-term industrial woodworking

- Works well with both softwood and hardwood

- Ideal for high-precision projects

.jpeg)

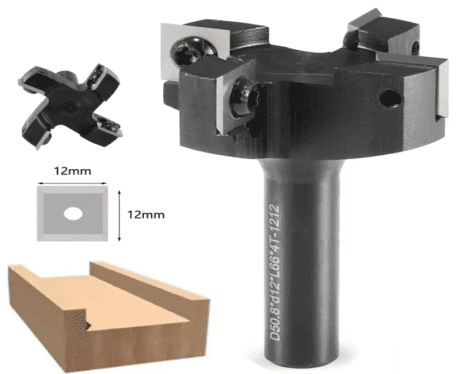

4. Indexable Turning Tools

Overview

Indexable turning tools allow users to rotate the blade to use multiple cutting edges before needing a replacement. This feature significantly extends tool life and enhances efficiency.

Key Features:

- Longer lifespan compared to welded tools

- No sharpening required, reducing downtime

- Supports coated and ceramic tool materials

- Lower overall tooling costs and simpler management

Best Applications:

- Automated, high-precision CNC woodworking

- Large-scale furniture and industrial production

5. Forming Turning Tools

Overview

Forming turning tools are custom-designed to create specific shapes in a single pass. These tools are shaped according to the desired workpiece contour, making them ideal for mass production.

Key Features:

- High precision and consistency in shaping

- Increases efficiency in mass production

- One-pass machining reduces labor time

Challenges:

- Higher manufacturing costs

- Potential blade vibration due to wider cutting areas

Best Applications:

- Mass production of small, identical parts

- Ideal for decorative woodworking

Choosing the Best CNC Woodturning Tool

Different woodworking projects require different lathe tools. Below is a guide to choosing the best tool based on wood type and application:

| Wood Type | Recommended Tool |

|---|---|

| Softwood | Normal lathe cutter, 3-in-1 wood lathe cutter |

| Semi-hardwood | Normal lathe cutter, carbide welding tool |

| Hardwood | Carbide lathe cutter with changeable heads |

| Mass Production | Indexable turning tool, forming turning tool |

| Precision Work | Forming turning tool |

For general woodworking, a 3-in-1 wood lathe cutter is recommended, while hardwood processing benefits from a carbide lathe knife with changeable cutter heads.