Woodworking Accessories Tips

HSK-63F Tool Holders: High-Performance Precision for CNC Machining

What is HSK-63F?

HSK stands for Hohl-Schaft-Kegel, a German standard for hollow taper shanks. The “63” refers to the flange size, while “F” denotes a specific form designed for automatic tool change systems. The HSK-63F interface provides both radial and axial contact, resulting in exceptional rigidity and precision.

✅ What Does HSK-63F Stand For?

-

HSK: Abbreviation for “Hohl-Schaft-Kegel” (German for Hollow Taper Shank).

-

63: Indicates the flange diameter in millimeters.

-

F: Refers to a specific HSK form designed for automatic tool change (ATC) systems without drive keys.

The HSK-63F system uses a short, hollow taper with dual-contact design—meaning it contacts both the spindle taper and face, resulting in higher rigidity and more accurate tool positioning.

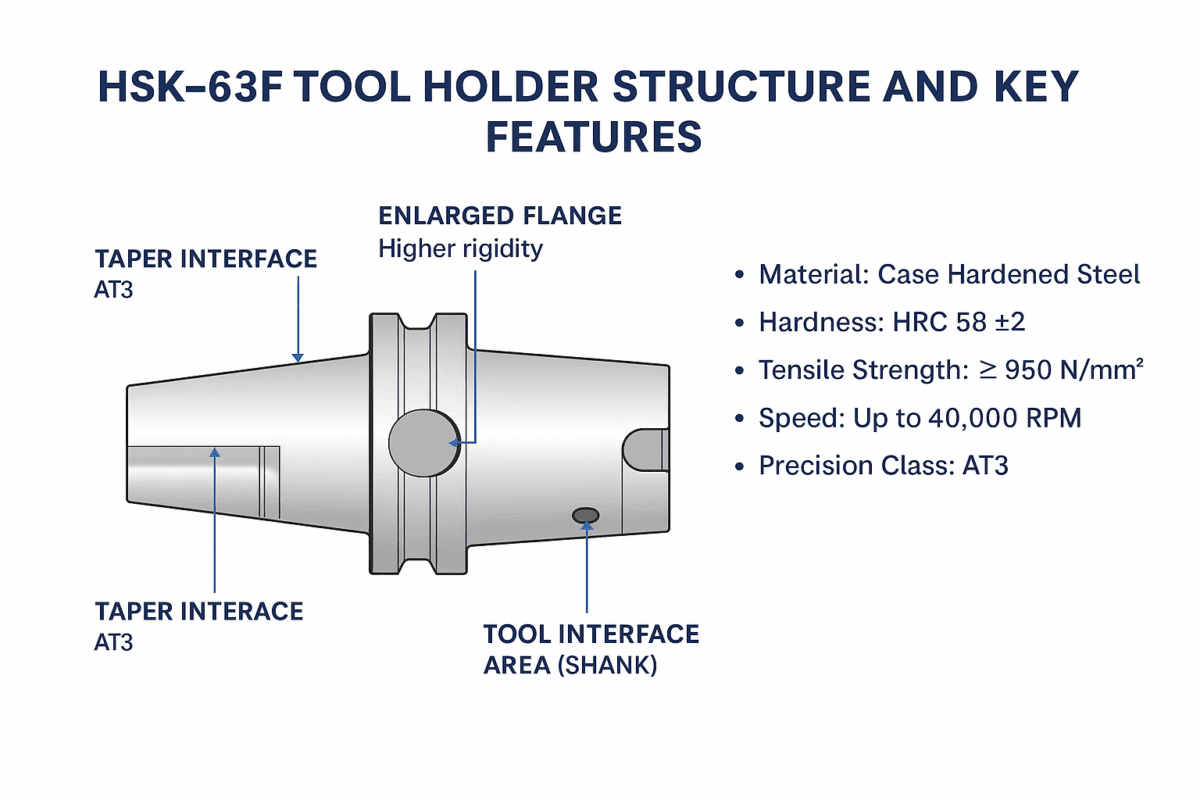

🔩 HSK-63F Tool Holder Construction and Material

-

Material: Case hardened steel

-

Core tensile strength: Minimum 950 N/mm²

-

Hardness: HRC 58 ±2

-

Case depth: 0.8 mm

-

Surface finish: Anti-corrosion silver finish

-

Precision class: AT3 taper accuracy

This robust build ensures durability under extreme rotational forces and temperature fluctuations common in high-speed CNC machining.

🚀 Top 7 Benefits of HSK-63F Tool Holders

1. Superior High-Speed Performance

HSK-63F holders are specifically designed for operations above 20,000 RPM. Their lightweight, balanced design reduces centrifugal distortion, allowing stable and vibration-free cutting at ultra-high speeds.

2. Dual-Contact for Maximum Rigidity

Unlike BT or CAT holders, HSK-63F makes contact with both the spindle taper and flange face, which:

-

Increases rigidity

-

Reduces axial movement

-

Improves cutting performance and surface finish

3. Unmatched Repeatability

Thanks to AT3 taper tolerance, HSK-63F ensures:

-

High concentricity

-

Low runout (typically <3 µm)

-

Precise tool changes even after hundreds of cycles

4. Fast and Reliable Tool Changes

HSK-63F is ideal for automatic tool changers (ATC). The symmetrical design and short taper enable:

-

Lightning-fast engagement and release

-

Reliable clamping under high load

-

Reduced machine downtime

5. Wide Range of Tool Compatibility

Available in different styles:

-

Shrink fit holders

-

Hydraulic expansion chucks

-

Collet chucks

-

Milling adapters

-

Boring bar blanks

This versatility makes it compatible with most cutting tool geometries and materials.

6. Better Tool Life and Surface Quality

Reduced tool deflection and minimal vibration:

-

Increase tool life

-

Decrease tool wear

-

Provide better machined surface finish

7. Ideal for 5-Axis Machining

Compact and lightweight design makes it suitable for:

-

Simultaneous 5-axis machining

-

Multi-sided milling

-

Precision contouring

🛠️ Typical Technical Specifications

| Feature | Specification |

|---|---|

| Taper Standard | DIN 69893-6, Form F |

| Flange Diameter | 63 mm |

| Drive Keys | None (Fully Symmetric Design) |

| Accuracy Class | AT3 |

| Material | Case Hardened Alloy Steel |

| Surface Treatment | Silver finish (anti-rust coating) |

| Application RPM | Up to 40,000 RPM |

| Usage | CNC Milling, Drilling, Engraving |

🔧 HSK-63F vs BT, CAT & SK Holders

| Feature | HSK-63F | BT / CAT |

|---|---|---|

| Contact Type | Dual (Taper + Face) | Taper Only |

| Speed Capability | Up to 40,000 RPM | Up to 12,000–18,000 |

| Tool Change | Faster, More Accurate | Slower, Less Repeatable |

| Rigidity | Higher | Moderate |

| Thermal Stability | Excellent | Average |

📌 Best Use Cases for HSK-63F Tool Holders

-

Aerospace parts with tight tolerances

-

Medical device component milling

-

Automotive mold and die applications

-

Woodworking CNC routers requiring high spindle speeds

-

High-speed engraving or multi-axis simultaneous machining

💡 Conclusion: Why Choose HSK-63F Tool Holders?

If you’re looking for faster cycle times, better part quality, and reliable tool changes—especially for high-speed, high-precision environments—HSK-63F tool holders are the ultimate choice.

Investing in HSK-63F holders helps manufacturers:

-

Reduce tooling downtime

-

Minimize part rejections

-

Extend tool life

-

Improve overall production efficiency