Woodworking Accessories Tips

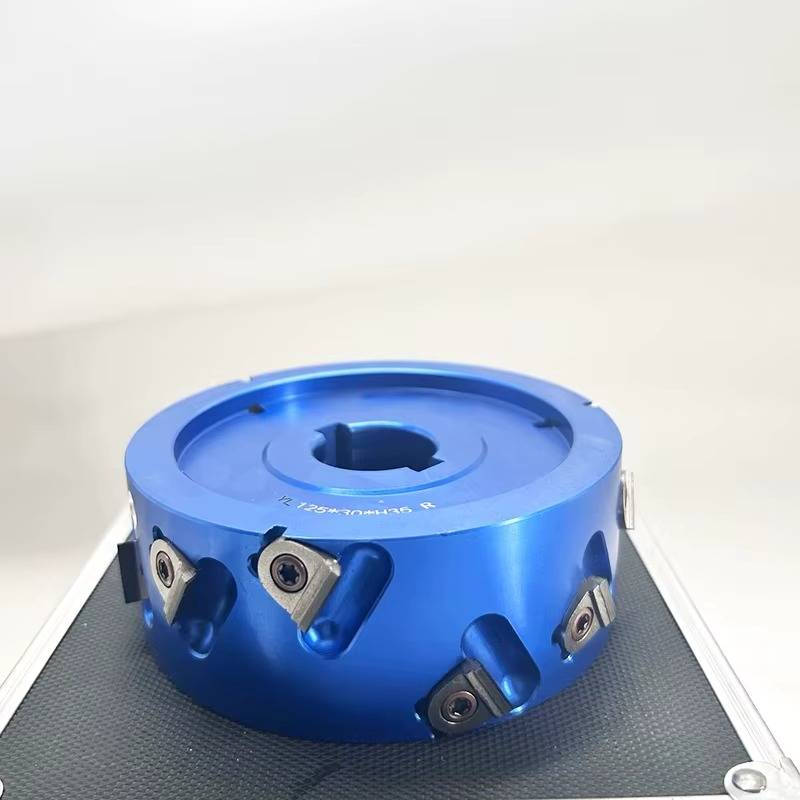

WhisperCut Pre-Mill Cutters with PCD Inserts: Precision Tooling for Edgebanders

What Is a WhisperCut Pre-Mill Cutter?

The WhisperCut Pre-Mill Cutter is a jointing milling cutter designed for the pre-milling station of edge banding machines. It features:

- Aluminum cutter body for reduced weight

- Replaceable/sharpenable PCD inserts (polycrystalline diamond)

- Symmetrical or asymmetrical cutting options

- Compatibility with top brands like Homag, Brandt, Biesse, IMA, Holz-Her

This cutter removes minor imperfections on the panel edge (chipping, glue residues, roughness) before the edge band is applied, resulting in a seamless finish.

Key Features

Lightweight Aluminum Body

- Reduces spindle wear and machine vibration

- Ideal for high-speed processing

Replaceable PCD Inserts

- Diamond-grade hardness for extended life

- Can be re-sharpened 3–5 times

- Easy to replace, reducing downtime

Adjustable Cutting Geometry

- Configure insert positions for symmetric or asymmetric cuts

- Supports various edge profiles and material types

Low-Noise Operation

- Engineered to minimize cutting noise

- Ideal for factories with strict noise regulations

Technical Specifications

Model Outer Diameter(mm) Height(mm) Bore(mm) Z

80X35X30 Z=3+3 80 35 30 3+3

100X43X30 Z=3+3 100 43 30 3+3

100X48X30 Z=3+3 100 48 30 3+3

100X63X30 Z=3+3 100 63 30 3+3

125X35X30 Z=3+3 125 35 30 3+3

125X43X30 Z=3+3 125 43 30 3+3

125X50X30 Z=3+3 125 50 30 3+3

125X65X30 Z=3+3 125 65 30 3+3

150X43X30 Z=4+4 150 43 30 4+4

150X55X30 Z=4+4 150 55 30 4+4

150X65X30 Z=4+4 150 65 30 4+4

Custom dimensions available upon request.

Compatible Machines

WhisperCut PCD jointing cutters can be used with:

-

Homag & Brandt edgebanders

-

Biesse WhisperCut systems

-

IMA Advantage machines

-

Holz-Her edgebanding lines

-

Also compatible with SCM, KDT, Nanxing, Laguna, Chisa, Giben, etc.

Materials It Works On

Perfect for processing:

-

MDF (medium-density fiberboard)

-

Chipboard

-

Plywood

-

Laminated board

-

Veneered surfaces

-

Melamine-coated panels

Advantages of PCD Tooling for Edgebanding

-

Extreme durability: PCD lasts 50–100x longer than carbide

-

High efficiency: Fewer tool changes mean higher uptime

-

Precision cutting: Minimal deflection ensures clean edges

-

Versatility: Suitable for abrasive and coated surfaces

Why Choose WhisperCut?

WhisperCut represents the next generation in pre-milling cutter technology, combining reduced machine load with unmatched edge quality. Ideal for high-throughput production lines and businesses focused on precision and longevity.

Conclusion

If your production depends on edge perfection, the WhisperCut Pre-Mill Cutter is the smart choice. Lightweight, durable, and quiet, it’s engineered for today’s fastest and most demanding woodworking lines.

Contact us today for pricing, technical support, or custom sizes.