Woodworking Accessories Tips

Can You Use a Router on MDF? A 3-Step Guide to Clean and Safe Cuts

Step 1: Understand MDF and Choose the Right Router Bit

Before you cut anything, it’s important to understand what MDF is made of and what that means for routing.

📌 What is MDF?

MDF is a man-made wood product created by compressing fine wood fibers with resin and wax. It’s:

-

Smooth and uniform, great for precision cutting

-

Denser than plywood, but not as strong as solid wood

-

Affordable, making it ideal for cabinetry, furniture, and decorative panels

But here’s the catch: MDF is abrasive, and cheap boards may contain impurities like resin clumps or small stones that can dull or damage router bits quickly.

❌ Router Bits You Should Avoid

If you’ve asked, “Can I use PCD router bits on MDF?” — technically yes, but it’s not recommended. PCD (polycrystalline diamond) bits are designed for clean materials. MDF’s inconsistencies can chip or destroy these expensive tools.

✅ Best Router Bits for MDF (CNC or Handheld)

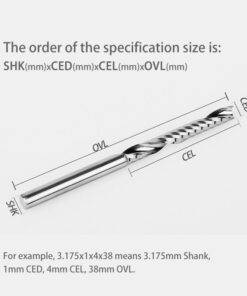

The best option is a solid carbide, double-flute, spiral up-cut bit:

-

Why it works:

-

Spiral design clears chips efficiently

-

Solid tungsten carbide resists heat

-

Smooth edges, long tool life

-

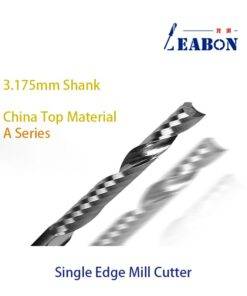

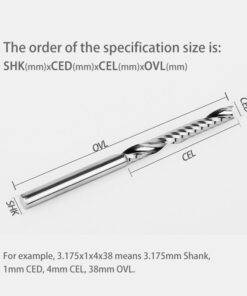

📌 Router Bit Recommendations (by MDF thickness):

| MDF Thickness | Bit Model | Diameter (mm) | Chip Load (mm/tooth) | Ideal Use |

|---|---|---|---|---|

| 1.8–1.2 cm | N2LX622 | 6 | 0.152–0.203 | Panel cutting |

| 1.0–0.7 cm | N2LX415 | 4 | 0.127–0.177 | Thin MDF projects |

| <0.7 cm | N2LX3.12 | 3.175 | 0.127–0.177 | Precision detailing |

⚙️ Step 2: Set the Right Feed Rate, RPM, and Chip Load

Once you have the right bit, the next step is adjusting your CNC or router settings for optimal performance.

🔁 Key Terms to Know:

-

RPM (Revolutions Per Minute) – spindle speed

-

Feed Rate – how fast the router moves across the material

-

Chip Load – how much material each flute removes per rotation

📐 How to Calculate Chip Load (And Why It Matters)

Chip load is the amount of material removed by each cutting edge of the router bit per revolution. It’s one of the most important factors in CNC routing because it directly affects tool life, surface finish, and cutting efficiency.

Formula:Chip Load = Feed Rate ÷ (RPM × Number of Flutes)

For example, using a 2-flute bit at 18,000 RPM with a 9,000 mm/min feed rate gives:9,000 ÷ (18,000 × 2) = 0.25 mm per tooth

👉 For MDF, aim for a chip load between 0.12mm–0.20mm per tooth.

🧪 Step 3: Test and Optimize Your Settings

Even if you’re using the perfect bit and the right numbers, testing is always a must.

✅ Test Strategy for Routing MDF

-

Start with recommended RPM (usually 18,000)

-

Slowly increase feed rate by 1 m/min at a time

-

Check for:

-

Rough edges → reduce feed rate or increase RPM

-

Burn marks → increase feed rate or lower RPM slightly

-

Material lifting → improve hold-down method

-

Your goal: Maximize chip size while keeping edges clean and tool wear low.

Common Issues & Fixes

| Problem | Cause | Solution |

|---|---|---|

| Rough edges | Feed too fast, dull bit | Slow down feed, use sharper bit |

| Burn marks | Bit rubbing, poor chip load | Increase feed rate or reduce RPM |

| Bit breakage | Wrong chip load or material | Recalculate settings, check MDF type |

| Poor hold-down | Weak vacuum or clamps | Use stronger suction or fixtures |